FUJIKO

Many products surrounding us increasingly utilize adhesive technology, making release liner one of the inevitable processing technologies. Whenever there is adhesive sheet, there is needs for “release paper and release liner”. Release liner, the sheet to be removed, protects the adhesive surface until its actual usage. Besides, it is critical that the released liner can be stripped-off properly at the usage time.

Adhesive sheet may sound simple at first; but its application is quite extensive, with many types available for different purposes. That is why the demand for release liner is not limited to easy release. To meet customers’ needs for different release liner performance, Fujiko have been utilizing a wide ranges of substrates materials.

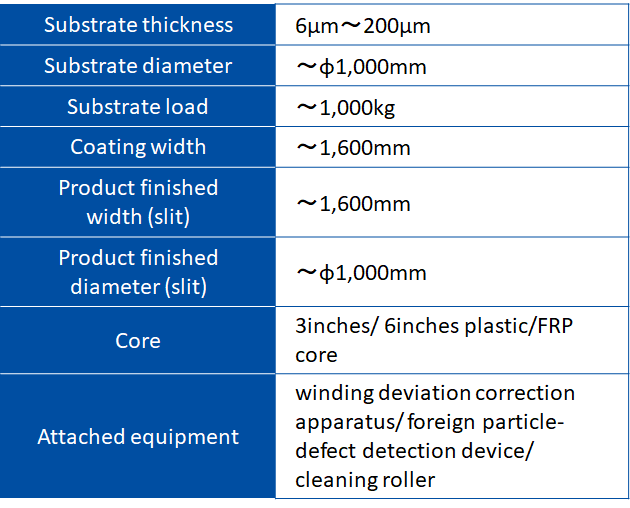

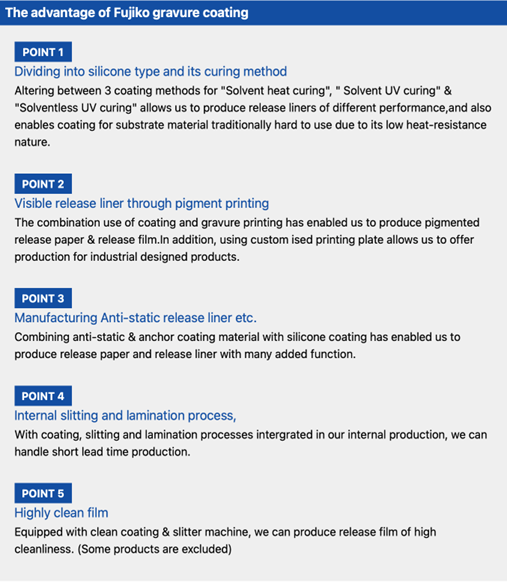

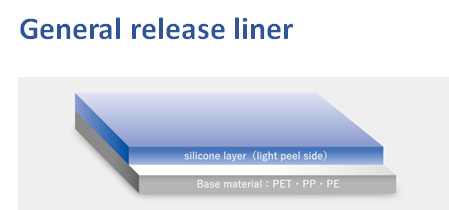

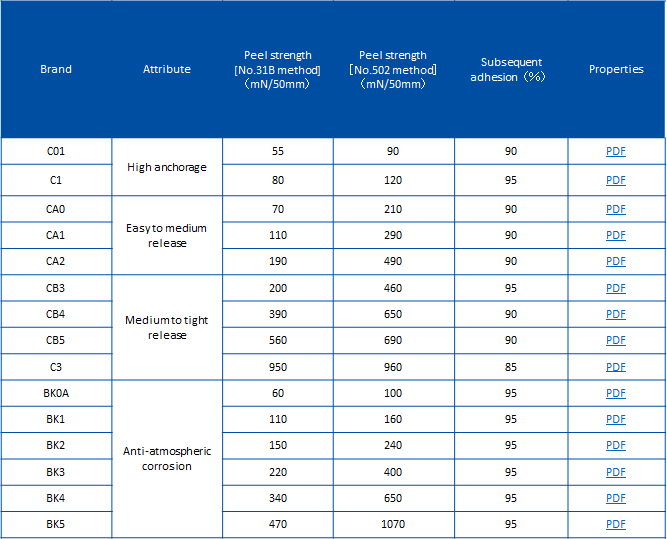

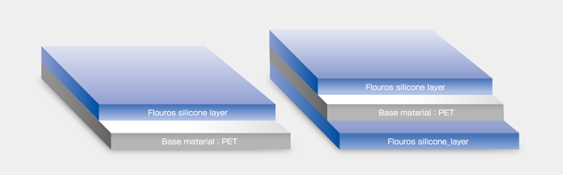

The most basic and common composition: coated silicone on either single or both sides of various substrate materials. The most basic and common composition: coated silicone on either single or both sides of various substrate materials. Apart from the listed specs, we also offer R&D collaboration for customized specs to suit your needs.

General Release Liner Types:

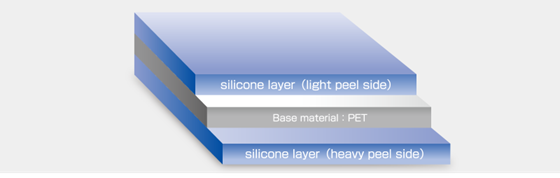

Differential release liners - double-sided

These products are made by coating silicone on both sides of various substrate materials. Creating different release force on each side makes both sides useable with tacky adhesive sheet etc. Difference in release force can be: Easy:tight as 1:3, or even larger gap in release force is adjustable. All specs under General release liner is combinable as front or back. Customized specs is possible as well. Fluoros silicone film, non-silicone film is also supported.

Application example

- For double sided tape

- For correction tape

- In making membrane of sticky resin, in winding, and as film for usage within processes etc.

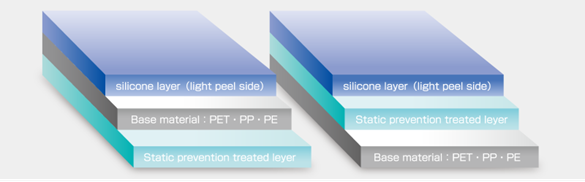

Anti-static treated release liner

Anti-static coat is either at the back of base material of silicone release liner, or at the layer below the release treatment layer coated on base material. Considering the usage, purpose and requirement of anti-static function, we select the suitable anti-static type. This is feasible for all the specs listed under General release liner, as well as all customized specs. It is also applicable for Fluoros silicone release liner, and non-silicone release liner.

Application example

- As part in manufacturing process of electronic materials

- Tape for construction materials etc.

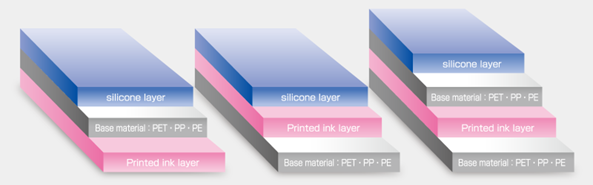

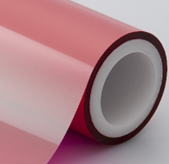

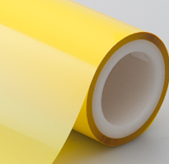

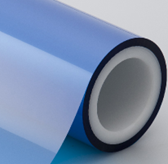

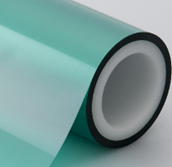

Colour release liner

The colour is printed by gravure printing on the back side of base material of silicone release coat, or on the layer below the release coating layer, or on the layer between 2 base material layers. Adding colour to the transparent clear release liner helps to enhance its visibility. Possible to select printing co lor. Moreover, if using customized printing cylinder, printing letter or pattern is also feasible. All standard specs listed in General release liner, customized specs as well as Flouros silicone release liner, and non-silicone release liner are supported. Colour is adjustable to your request.

Application example

- For double sided tape

- For correction tape

- In making membrane of sticky resin, in winding, and as film for usage within processes etc.

【Colour variations】

Shades and concentration level of printing colour can be adjusted freely.

Flouros silicone release liner

Make it possible to produce release liner with very easy release, even for silicone adhesive that usually damages the releasability of common silicone release liner.

Application example

- Silicone adhesive tape base material

- Release liner used for heat-resistant masking tape (polyimide)

- For silicone type resin etc.

Non-silicone release liner

For applications that silicone is not allowed due to its usage purpose (silicone residue is unacceptable)

Non-Silicon Release Liner Types:

| Brand | Attribute | Peel strength (mN/25mm) | Angle of contact (degree) | Properties |

|---|---|---|---|---|

| HP-A0 | Non-silicone | 250 | 105 | |

| HP-A | 2000 | 98 | ||

| HP-A3 | 4000 | 94 | ||

| HP-A5 | 7000 | 83 | ||

| HP-TY1R | Non-silicone | 3000 | 93 | |

| HP-TY3R | 4000 | 90 | ||

| HP-TY5R | 6000 | 88 | ||

| HP-SA | Silicone modified resin | 500 | 100 | |

| HP-SA2 | 1000 | 100 | ||

| HP-SA3 | 1500 | 98 | ||

| HP-SA4 | 2000 | 97 | ||

| HP-SA5 | 2700 | 95 |

Fujiko provides products of high cleanliness and has been raising factory standards by equipping high-tech manufacturing facility, testing equipment as well as improving skills of our staff.

Clean room slitters(class1,000)

Air shower

【Main advantages】

- Capable to support substrates width up to 1600mm

- Possible for combination use of thermal cured and UV cured system.

- Possess 3-coating head machine, which allows 3 coating at one pass production.

(Front side: 2 coating, Back side: 1coating) - Coating room: Class 10000

Coating head: support clean coating at Class 100

【Manufacturing system】