SHIFTING BASE ASSEMBLIES

CUSTOM ENGINEERED SHIFTING BASE ASSEMBLIES ARE MANUFACTURED WITH ANODIZED ALUMINUM PLATE OR STRUCTURAL STEEL TUBE TO PROVIDE SUPERIOR PERFORMANCE AND RELIABILITY.

AccuGuide Unwind/Winder-Rewind Shifting Base assemblies are manufactured in two construction methods. Structural steel tube (SB-FS Series) is used for wide web or high tension applications and anodized Aluminum plate (SB-AP Series) is used for mid to narrow webs. The low coefficient of friction linear bearing systems provide superior long term reliability and accuracy.

Shifting base assemblies are custom engineered to suit each application. Uprights and mounting surfaces are designed to accommodate tension/safety chuck systems. These assemblies come ready to install with pre-designed mounting feet that are level and tram.

Heavy-Duty FS Series Structural Steel Tube — Provides exceptional strength and design flexibility for wider web or higher tension applications.

Low-Inertia AP Series Aluminum Plate Design — High strength-to-weight ratio allows fast frequency response in mid-to-narrow web configurations.

Linear Bearing System — Precise, low coefficient of friction, linear bearing assemblies are chosen to suit each application.

Easily Adaptable — Shifting base assemblies are custom designed to easily integrate with existing unwind or rewind stands.

Easy Wipe Down — Smooth, anodized flat surfaces are simple to maintain in clean room environments.

Free-turning Idler Rollers — Free-running bearings minimize rotational torques – ideal for running light webs. Dynamically balanced rolls ensure vibration-free performance. Choose from live shaft or dead shaft options.

Edge Chasing and Edge Positioning — Custom models available to follow web position.

An AccuWeb® System is a Sound Investment

- Tangible Benefits — While web guides represent a nominal expense within an entire converting line, they can have considerable impact on product quality, process waste, operating speeds, efficiency and maintenance costs. Choosing a web guide system that delivers optimum trouble-free performance is a wise investment.

- The Support of Web Guide Experts — The AccuWeb application engineering team helps you determine the best guide design and location to fit your specific converting operation. By evaluating your web widths, materials and change-over frequencies, as well as operating environment, AccuWeb helps ensure greater harmony between our innovative guide components and your web converting process for an optimum return on your investment.

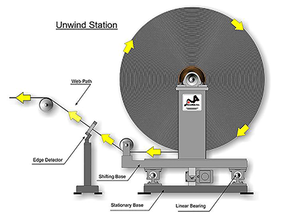

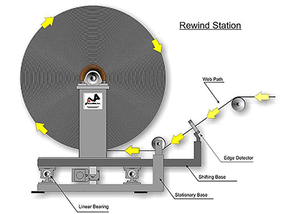

Typical Unwind/Rewind Web Guide Layouts

Typical Unwind/Rewind Web Guide Layouts

Unwind Guiding sidelays the entire roll of material to maintain a consistent edge position as the web enters into the process. An AccuGuide Unwind guide assembly positions the web edge to the guide point. The edge detector is stationary and located immediately following the last shifting idler roller on the unwind stand. An unwind guide eliminates problems such as uneven, telescoped or poorly wound rolls.

Winder/Rewind Guiding is accomplished by moving the roll of material to match the edge position of the web as it exits out of the process. An AccuGuide Rewind chases the web to keep it aligned properly on the rewind core. The rewind edge detector is attached to the moving rewind stand and is positioned on the upstream side of the last fixed idler roller.

Winder/Rewind Guiding is accomplished by moving the roll of material to match the edge position of the web as it exits out of the process. An AccuGuide Rewind chases the web to keep it aligned properly on the rewind core. The rewind edge detector is attached to the moving rewind stand and is positioned on the upstream side of the last fixed idler roller.

Rewind guides create rolls with precise, even edges or can be used to oscillate, eliminating gage band problems.

The moving frame pivots around an adjustable, theoretical pivot point on the incoming web span to maintain the desired web position. Linear bearing assemblies are factory set for each application.

Shifting Base FS Frame Options

- Electrolys nickel

- Stainless steel

- Smooth welds

- Walkways

- Custom paint colors

Shifting Base AP Frame Options

- Hard-coat anodized aluminum

- Black anodized aluminum

- Stainless steel

Roller Options

- Plasma Coated

- Rubber Covered

- Hard-coat Anodized

- Cork Covered

- Micro-grooved

- Teflon

Model Nomenclature: