ROTARY POSITIONING

MECHANICAL INDEXERS

For more than 50 years, Camco global products have been the industry standard for the highest quality cam-actuated, motion control products available. Camco Indexers and Servo Drives assist with device indexing. Indexing is the starting and stopping of a device in precise intervals at precise locations. DESTACO’s Camco cam-operated rotary indexers move a wide variety of products and components with precision.

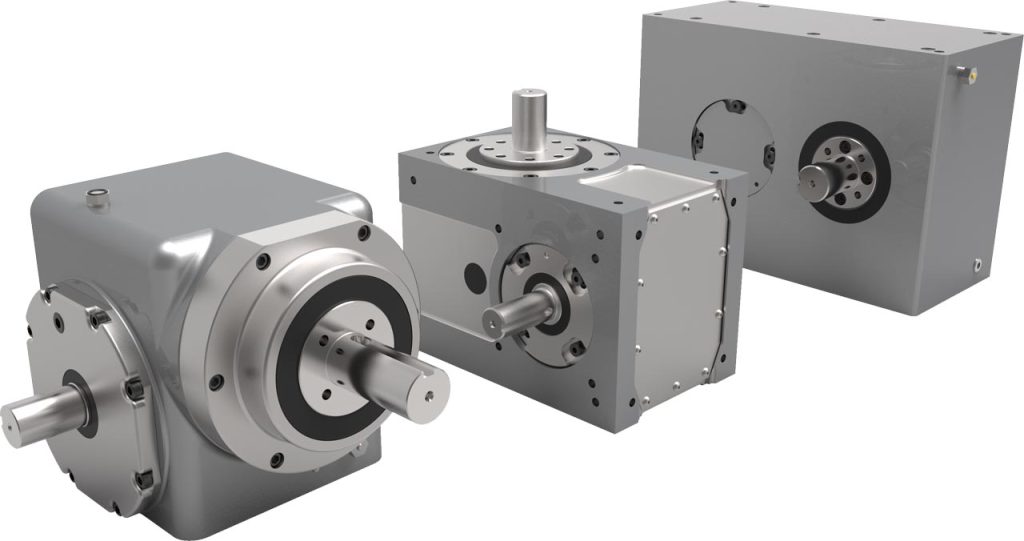

CLUTHES

DESTACO’s CAMCO Output Overload Clutches and Torq/Gard Clutches protect equipment from costly downtime, quickly disengaging the drive system in overload or jam conditions. A range of models is designed for all applications, with standard and custom trip torque capacities. The CAMCO overload clutches’ single-position reset function maintains accuracy and machine timing.

PART HANDLERS

When precise parts handling and pick-and-place capabilities are part of your automated system application, turn to DESTACO’s CAMCO parts handlers for the ideal Rotary or Linear configuration. No matter what your system demands—high speed, high load, high capacity—DESTACO’s CAMCO parts handlers deliver consistently reliable precision.

ROTARIES

DESTACO’s Robohand Pneumatic Rotary Actuators (Rotaries) are available in a wide range of models: Shaft or flange output, high or low precision, light-duty to heavy-duty. Some models feature the DirectConnect hole pattern for easy integration with other Robohand products – no adapter plates! DRF Flange Rotaries with DirectConnect offer easy integration with other Robohand products and for applications requiring a precision end stop and zero backlash. DRG Shaft Output Rotaries with DirectConnect for applications where low precision, end-stop positioning and backlash are acceptable.

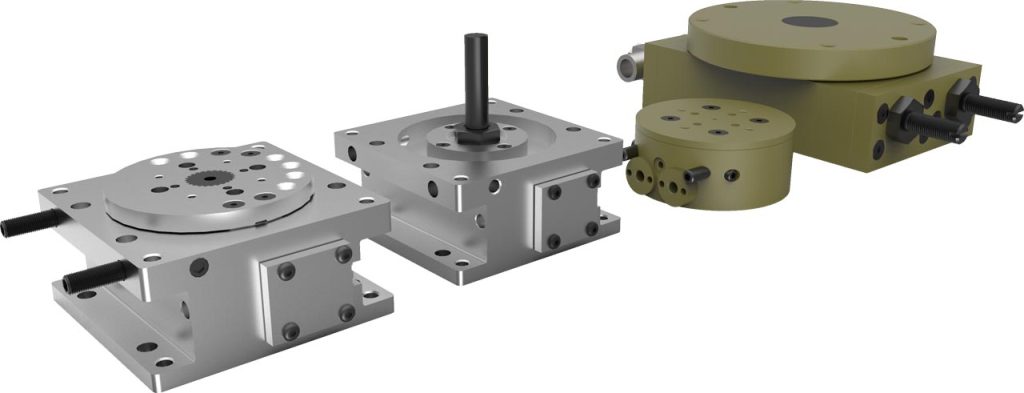

SERVO POSITIONERS

Camco offers a range of high performance servo positioners for light to heavy duty applications. The series also features large, center thru-holes and zero backlash mechanisms. Larger positioners can rotate several tons of automotive body parts in seconds while smaller Parallel and Roller Gear indexing drives accurately index pharmaceutical or electronic components in milliseconds. Servo positioners are ideal for when the number of stations needs to be flexible and accommodate different parts. The index motion time and dwell time are changed by programming the motion profile of the servo motor. These models are easily integrated into a multi-axis system, can attain 60+ cycles per minute, and are able to monitor process parameters – such as cycle rate, uptime/downtime, and power demand.