PRESCALE

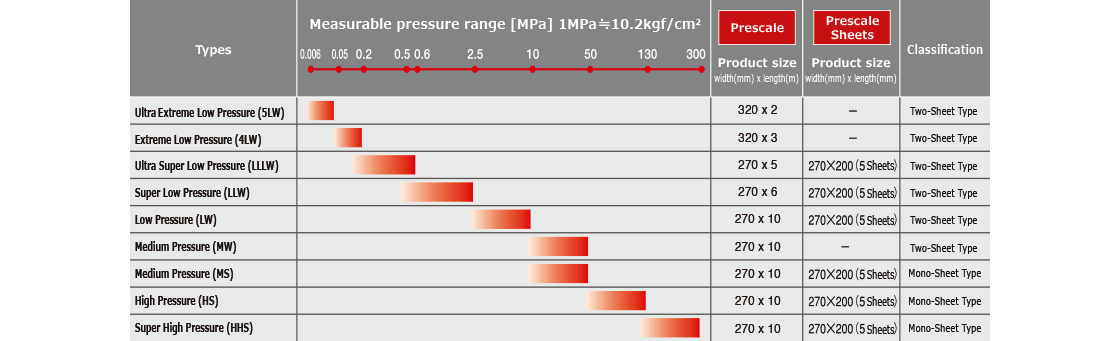

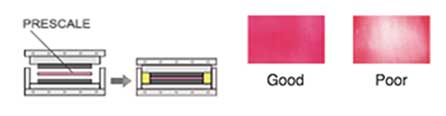

Prescale allows you to easily measure pressure distribution and range. Created using Fujifilm’s advanced thin film coating technologies, the pressure inspection sensor on the entirety of the film allows you to confirm pressure distribution of the entire surface at a glance. The colour appears red where pressure is applied, and the colour density varies according to the amount of pressure. To cover a wide pressure range (0.006 to 300 MPa), Fujifilm Prescale excellent for the applications below:

Prescale Applications:

1)Nip Pressure

Industries: Battery, Paper manufacturing, printed circuit board, electrode plate pressing, display, Rubber roller mounting quality, etc.

Adjustment of calendar roll pressure balance

Checking for wear on press rubber roller when changing paper sizes

Assessment of rubber roll mounting quality

Check for roller damage or alignment used for pressing electrode plates

2) Lamination Pressure

Industry: Printed Circuit Board(PCB), Lead frames, Liquid crystal, semiconductor production, touch panel & LCD productions, etc.

Examples of lamination pressure measurement using Prescale.

Checking adhesive pressure of dry film resist (DFR) lamination

Checking drum (roller) pressure uniformity

Verifying backgrind tape lamination pressure uniformity

Checking roller pressure uniformity when attaching the cover glass to touch panels or LCDs.

3) Winding pressure

Industry: Functional film, Paper, Coated paper, Functional paper

Stress pressure distribution during winding (paper, Film, coating)

4) Contact pressure

Checking the fitting of the brake pads of disc brakes (Automotive)

5) Compression pressure

Industry: Solar cells, Electronic components, OLEDs, Touchscreens, Print circuit boards, Equipment such as semiconductors that are used as manufacturing and development machines

Verification of pressure uniformity of vacuum heat pressure devices

Setting of vacuum laminator (Solar cells)

Checking mould contact and pressure uniformity (Laminating Machines)

Checking the water resistance of mobile phones

Ensuring high-quality thermocompression bonding by the application of uniform pressure (Bonding equipment, silicon wafer)

Checking uniformity of cell lamination load distribution (Fuel cell manufacturing)

6) Contact conditions

Check pressure uniformity between the polisher stage (Semiconductor)

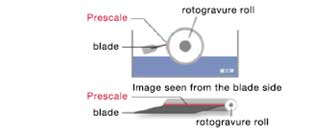

Analysis of blade pressure when uneven coating thickness occurs (Film)

Verifying CMP polishing head contact uniformity (Semiconductor)

Equipment maintenance on Heat Sealing (Packaging)

Verifying CMP polishing head contact uniformity (Semiconductor)

Adjustment of molds and injection molding machines (Injection moulding)

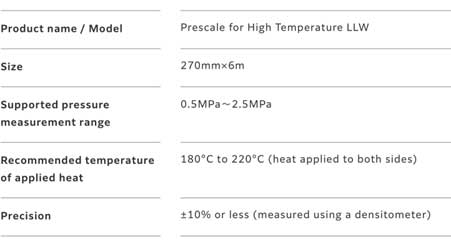

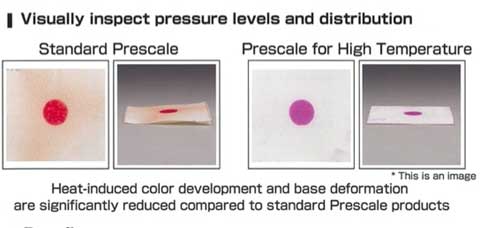

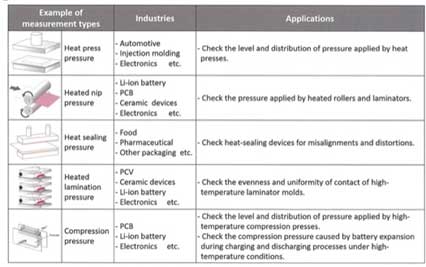

Prescale for High Temperature (180°C to 220°C ) LLW. Pressure measurement film for use under high-temperature conditions. Measure pressure in cases where heat and pressure are applied simultaneously with ease.