POINT SOURCE

DYNAMICALLY COMPENSATED EDGE DETECTORS FOR SINGLE POINT WEB GUIDE ACCURACY ─ USING ULTRASONIC OR INFRARED TECHNOLOGY.

Point Source edge detectors utilize a unique two beam system that continuously monitors the energy transmitted, while automatically compensating for minute environmental changes to maintain consistent guide point. This means improved web accuracy and reliability with less downtime.

Even in the harshest environments, no other edge detector gives you more accuracy and reliability.

Dynamically Compensated — Our exclusive technology automatically adjusts for all environmental, process and web changes — temperature, relative humidity, barometric pressure, dirt, dust, Oxi-Dry, nitrogen additions, web flutter, or passline variations.

Any Web Material — AccuWeb’s compensated edge detectors are available in ultrasonic and infrared technology to effectively guide all web materials — paper, film, foil, nonwovens, mesh, metals — regardless of opacity level or density. Select either ultrasonic or infrared models depending on materials.

Hazardous Duty Operation — Intrinsically safe models are available to operate in Class I, Division 1 Group C&D hazardous environments.

Special Applications — High temperature models available for ovens up to 500°F (260°C). Infrared models available for vacuum environments to 10-6 Torr.

Totally Automated — No Maintenance — Our compensated edge detectors self-calibrate automatically. No operator adjustments necessary – resulting in faster make-ready. Other than an occasional wipe down, no maintenance is required.

You’ll always get more value from AccuWeb

- Every AccuWeb edge detector has our exclusive dynamic compensation technology.

- Hard-coat anodized aluminum or custom engineered polymer housings provide extremely durable, yet light-weight edge detectors.

- Specially designed compensated ultrasonic versions are available for high temperature applications up to 500ºF (260ºC).

- Stainless steel and waterproof options are available for wet or harsh environments.

The advantage of dynamic compensated technology

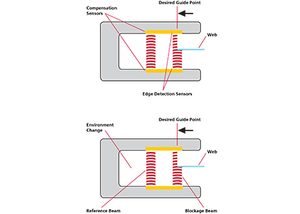

Two beams of pulsed energy are transmitted across the detector gap.

Two beams of pulsed energy are transmitted across the detector gap.

The amount of energy received by the Edge Detection Sensor is converted to a digital web position signal. The amount of energy received by the Compensation Sensors provides a continuous reference signal to eliminate guide point drift due to changes in temperature, humidity, dust, dirt, ink overspray, web flutter, passline variations or other environmental factors.

As environmental conditions change, the Compensation, or Reference Beam, monitors the conditions in real time and proportionally adjusts the web detection beam to maintain the original guide point.

Specifications

Temperature Range:

- 32ºF (0ºC) – 185ºF (85ºC)

Construction:

- Anodized aluminum, stainless steel, or engineered polymer (available washdown options)

Linearity:

- 0.5% – 3.0% over entire temperature range

Edge Detector Dimensions

| Model | Dimensions – Inches (mm) | ||||||

| A | B | C | D | E | F | Drawings | |

| 1.5×3 | .88 (22) | 3.00 (76) | 3.50 (88) | 0.25 (6) | 2.75 (70) | 1.50 (38) | AB-6293 |

| 3×3 | .88 (22) | 4.50 (114) | 3.50 (88) | 0.25 (6) | 2.75 (70) | 3.00 (76) | AB-6649 |

| 4×6 | .88 (22) | 5.50 (140) | 6.75 (171) | 0.25 (6) | 6.00 (152) | 4.00 (102) | AB-8235 |

| 4×12 | .88 (22) | 5.50 (140) | 13.25 (372) | 0.25 (6) | 12.00 (305) | 4.00 (102) | AB-6442 |

Mounting Bracket Options:

E/DBKT 6000-04 Manual Adjust Edge Detector Bracket mounts to a 1″, or 25mm, square bar

E/DBKT 6001-04 Micrometer Adjust Edge Detector Bracket mounts to a 1″, or 25mm, square bar