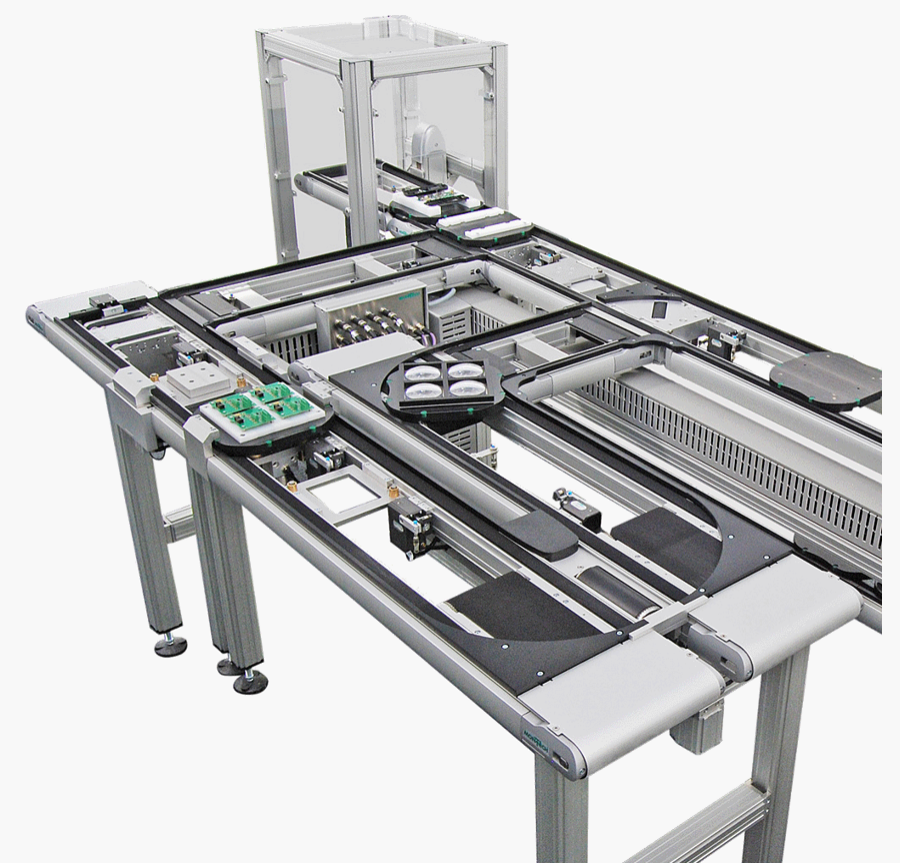

TWIN BELT LT40 TRANSFER SYSTEM

LT40 Transfer System

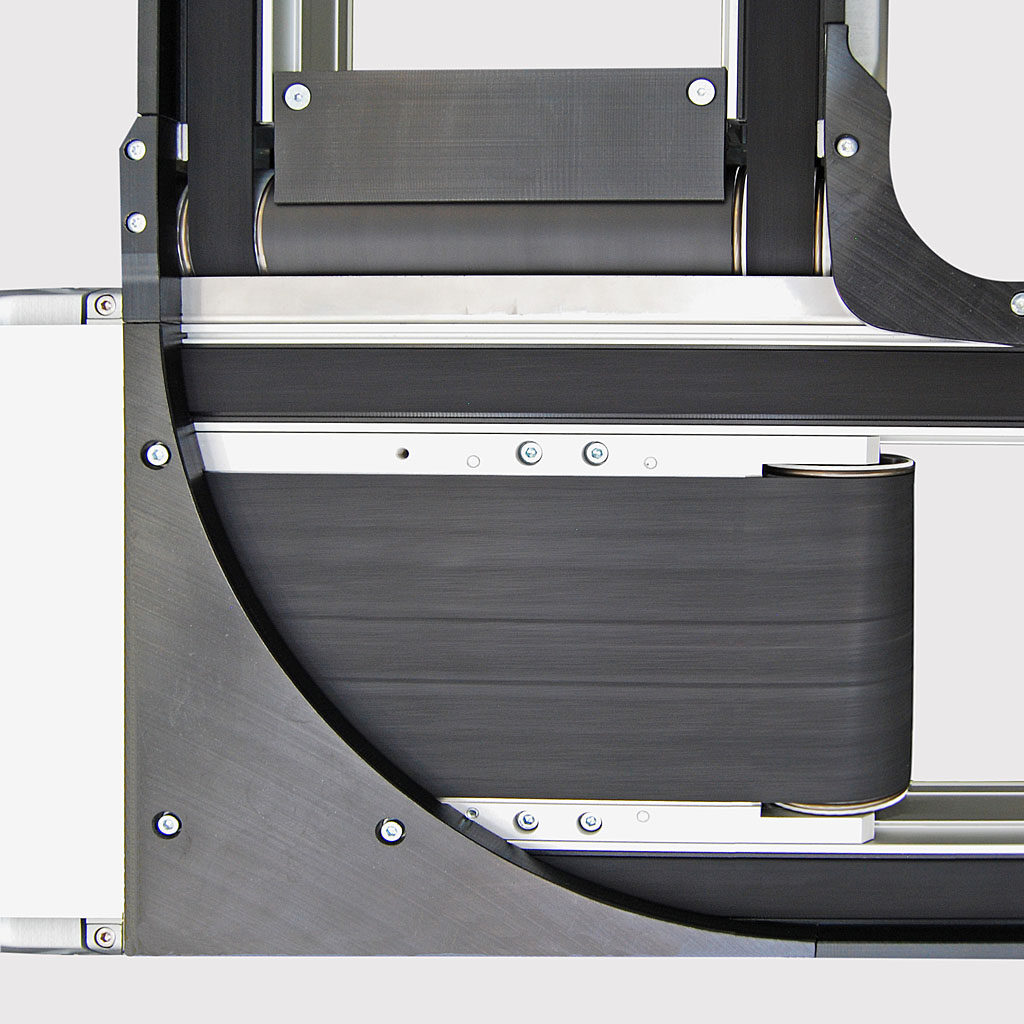

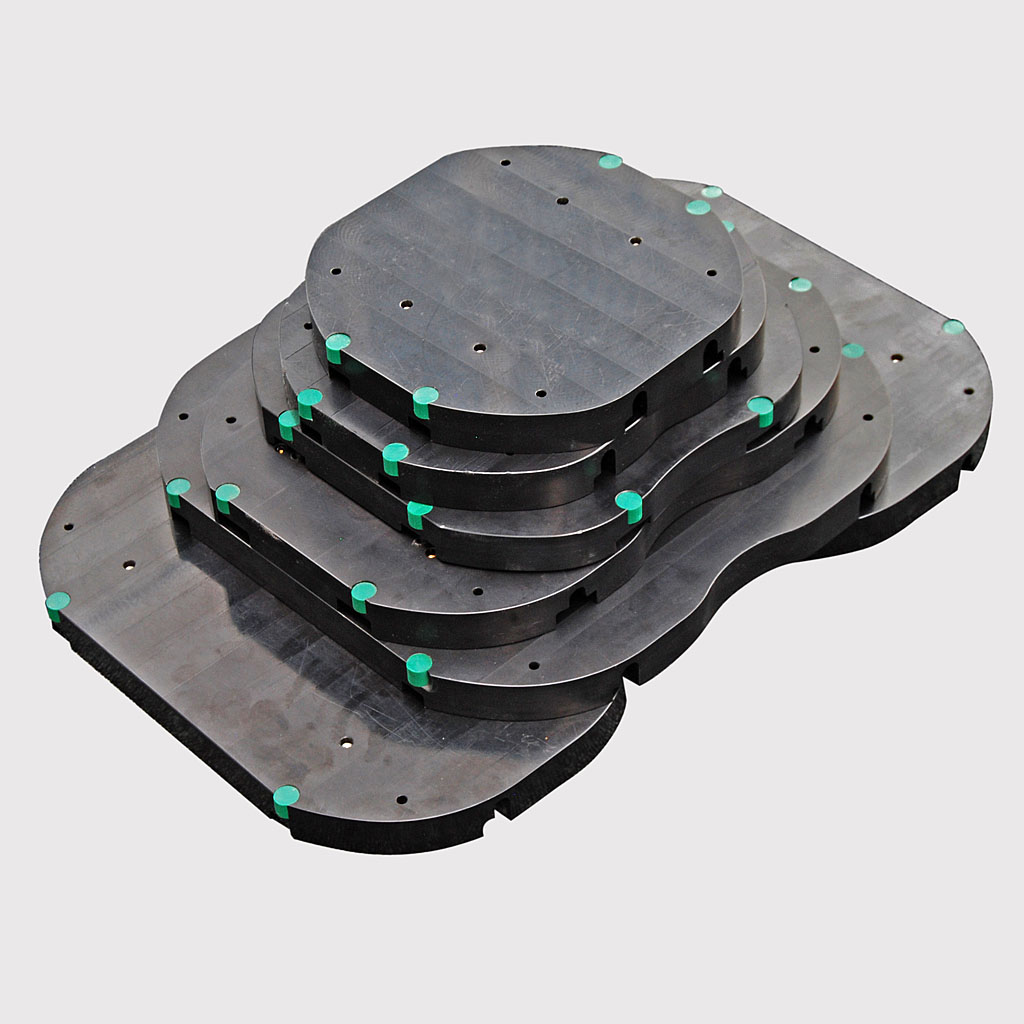

The LT40 transfer system is a dual toothed belt system on which individual transfer plates or product carrier run at a speed of up to 20 m/min. The LT40 is available in three sizes, so there is an optimal configuration for every application. The transfer plates or product carrier come in six different sizes and can accommodate loads up to 16.8 kg. They can be equipped with RFID so that they can be identified at any time. The conveyors are designed to customer specifications, and two types of drive controllers are available to regulate speed.

Transfer plate or product carrier are diverted by lateral transport, 90° deflection, 180° deflection or a switch. The shock-absorbing pneumatic separating unit / stopper, which is used as a stopper and pre-stopper, is used for stopping, separating and decelerating one or more incoming workpiece carriers. All components can be easily moved into any position because of the dovetail guide.

To execute operations on the transfer plate or product carrier, an indexing unit, which is integrated in the conveyor, or a positioning unit with 1000N pressure and a placing unit with up to 60 kN vertical load are available. A lifting / turning unit or a lift can be installed on the transfer system upon request.

The LT40 transfer system features efficiency-optimized, energy-efficient motors. They not only meet the minimal EU requirement for efficiency class IE3, but they also exceed the Super Premium efficiency class IE4 planned for the future.